Ai Vision Systems The Key To Quality In Additive Manufacturing

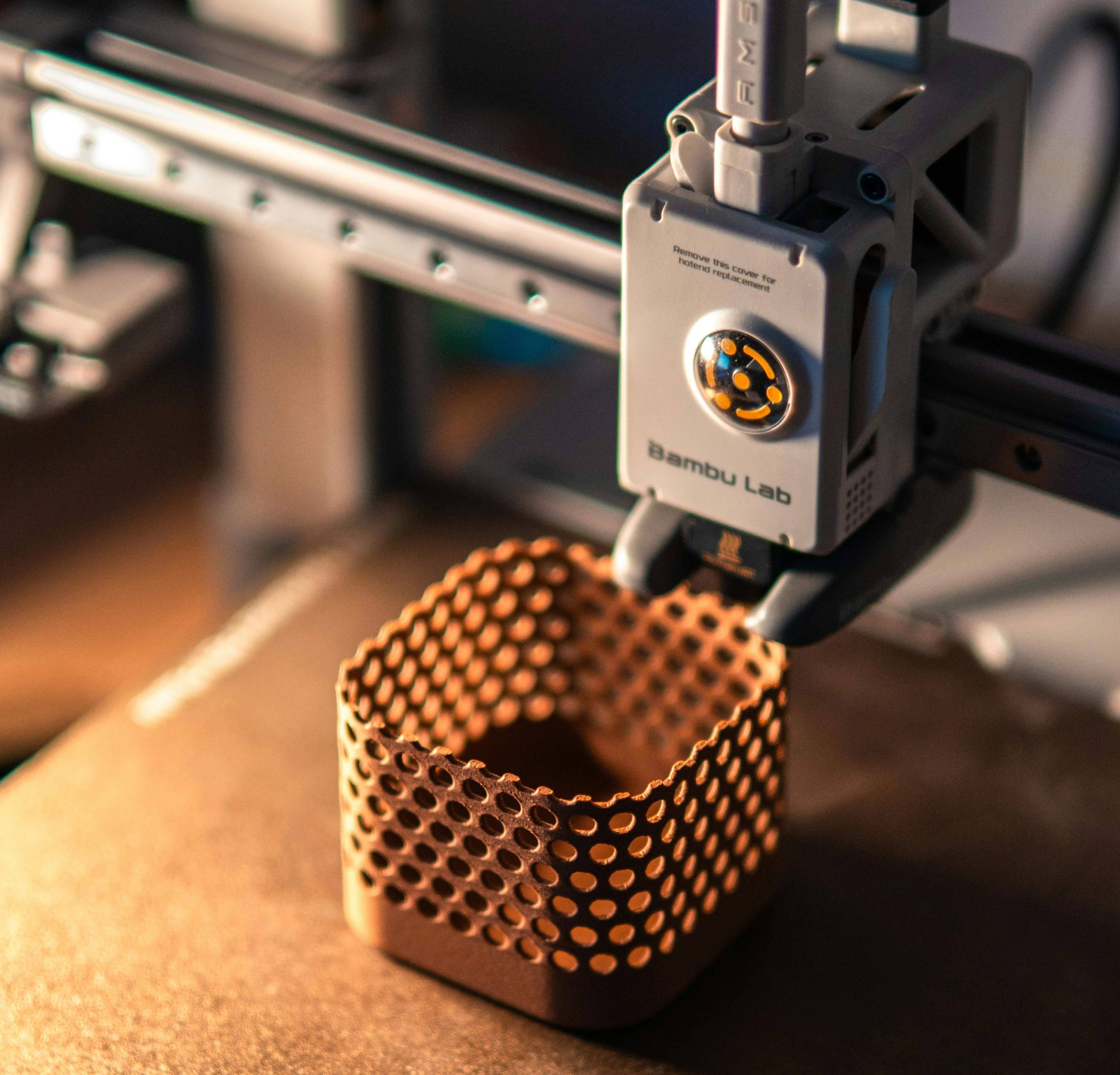

Additive manufacturing (AM) is transforming industries such as aerospace, automotive, and healthcare by enabling the production of complex, lightweight, and customized components. Yet, despite its enormous potential, adoption remains limited. Why? Because persistent challenges—like defects and geometric inaccuracies in 3D-printed parts—continue to undermine reliability and scalability. In sectors where precision is non-negotiable, even the smallest deviation can compromise safety and performance, making rigorous quality control an absolute necessity.

This is where AI-driven vision inspection systems come into play. These solutions combine advanced machine learning with computer vision to deliver real-time, high-precision defect detection. By identifying micro-defects and inconsistencies early, manufacturers can reduce waste, optimize resources, and lower operational costs. Even more compelling, AI systems continuously learn and adapt to new defect patterns, making them indispensable for high-stakes applications where reliability is critical.

Achieving this level of accuracy depends on two critical steps: image acquisition and defect detection. Image quality—shaped by camera resolution, lighting conditions, and environmental factors—directly impacts feature extraction. Improving datasets and acquisition methods to reflect industrial realities, such as varying angles, positions, and shapes, is essential for robust multi-modal defect detection.

Traditional machine learning approaches have been effective for detecting surface flaws like scratches and abrasions using two-dimensional images. However, 2D imaging falls short when it comes to complex AM defects such as cracking, porosity, residual stresses, and balling—issues that often occur internally or across multiple layers.

Deep learning offers a powerful alternative. Using convolutional neural networks, it transforms raw image data into high-level features for accurate defect classification. Still, building a sophisticated neural network capable of real-time defect classification remains challenging due to the diversity of AM processes and part geometries. It requires distributed embedded intelligence that can continuously learn new defect patterns across multiple locations. To achieve this, a low-latency computing platform that supports parallel processing is essential for deploying AI inspection systems at scale.

As AM adoption accelerates, AI vision systems will play a pivotal role in ensuring quality and reliability. Manufacturers that invest in these technologies today will not only reduce risk and cost but also position themselves at the forefront of smart, automated production.